The new Baffle Arm is directly interchangeable with industry standard Pantograph Baffle Arms allowing for a straight forward installation onto the machine, reducing setup times and associated costs.

The new Baffle Arm development has been engineered to optimise performance and reduce wear on mechanisms while also minimising cost to the user.

The new Baffle Arm is directly interchangeable with industry standard Pantograph Baffle Arms allowing for a straight forward installation onto the machine, reducing setup times and associated costs.

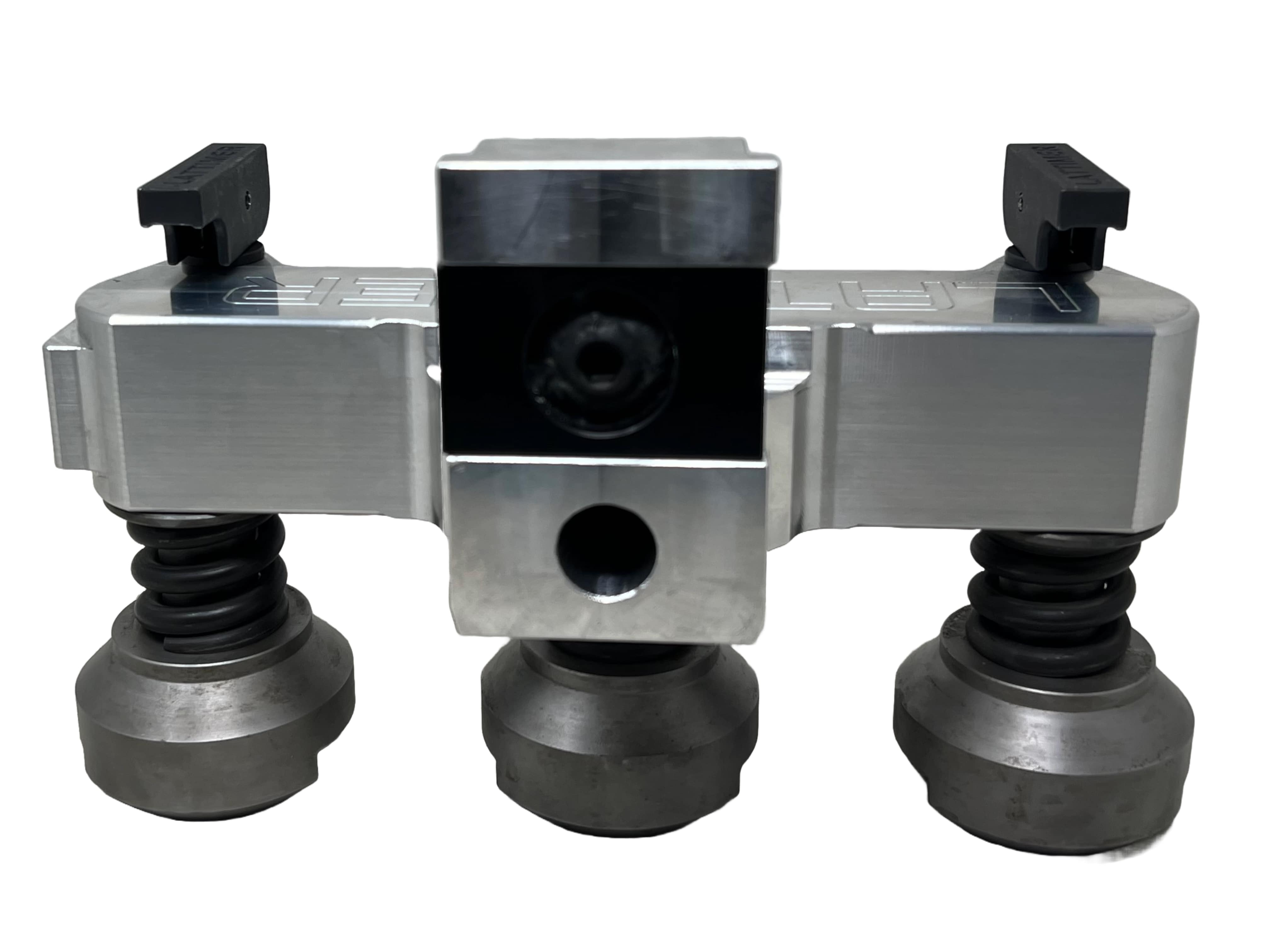

The new Baffle Arm development has been engineered to optimise performance and reduce wear on mechanisms while also minimising cost to the user. The new simplified design produced from 7075 billet aluminium reduces weight and assembly parts by over 45%, reducing points of failure and

maximizing reliability. As proven in similar Lattimer developments, the individually sprung concept has been adopted into this design to improve the cross-cavity equalisation.

The new design with high tensile springs allows the load to be evenly distributed across cavities, reducing container defects.

The reduction in assembly parts delivers a new simplified design. This new design minimises inventory cost for the user while also reducing frequency of servicing.

This product is designed to meet the evolving needs of the Glass Industry requiring efficiency improvements and operational cost reduction.

_355_355_c1.jpg)

CREATING A NEW VISION FOR GLASS ENGINEERING

Quick

Contact